Our Services

Your Tool-Building & Product Development Partner

As your trusted CNC machining tool builder and product development partner, Avantech is providing more value than ever before. We offer our customers comprehensive solutions to tool-building challenges, product design and development, and tool revision and refurbishment, all undertaken by the experienced and knowledgeable Avantech team.

Our People & Equipment Make the Difference

CNC Machine Tooling

Dimensional precision. Speed-to-market. Exact repeatability. A surge of demand for these manufacturing qualities has rapidly expanded the use of CNC machined aluminum tools in the roto molding industry. To keep our customers ahead of the technology curve, Avantech has made a multi-million dollar investment in CNC machine tooling capabilities. Through our cutting-edge equipment and proven process, Avantech can deliver tools of all sizes and complexity quickly and cost-effectively to customers around the world.

Any Size, Any Complexity

The Avantech team can handle tool machining for projects of virtually any size and complexity thanks to the experience of our people, our advanced technologies, and 16 dedicated CNC machining centers.

Cost-Effective

Superior Speed-to-Market

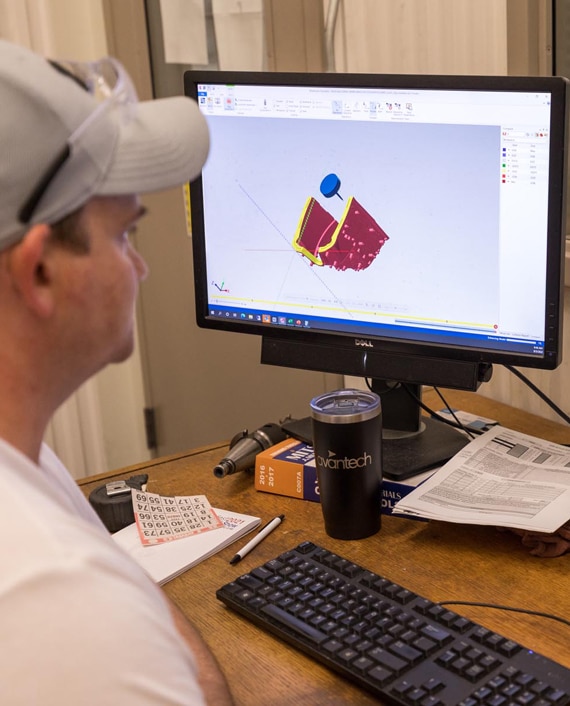

Product Development

Avantech has brought to bear our over 30 years of experience servicing the rotomolding industry for our clients, partnering with them to design and develop products that optimize the aesthetics, functionality, and cost-effectiveness of rotomolding. With our multidisciplinary manufacturing capabilities, Avantech’s single-source product development can make your concept a reality and help you bring exciting new products to a global marketplace.

Think

Create

Advance

Tool Repair & Refurbishment

Avantech is proud to have developed a highly-skilled team, robust capabilities, and a proven process dedicated specifically and exclusively to providing top-quality tool repair and refurbishment services. Our tool refurbishment and revision solutions prioritize return on investment and value-add service.

Analysis

Our tool revision process begins with a thorough analysis of the customer’s updated product design to ensure manufacturability and quality.

Development

Optimization

Our tool refurbishment capabilities enable customers to optimize tooling longevity by maintaining proper working conditions of parting lines, clamping and closure mechanisms, air management systems, and ancillary tool components.